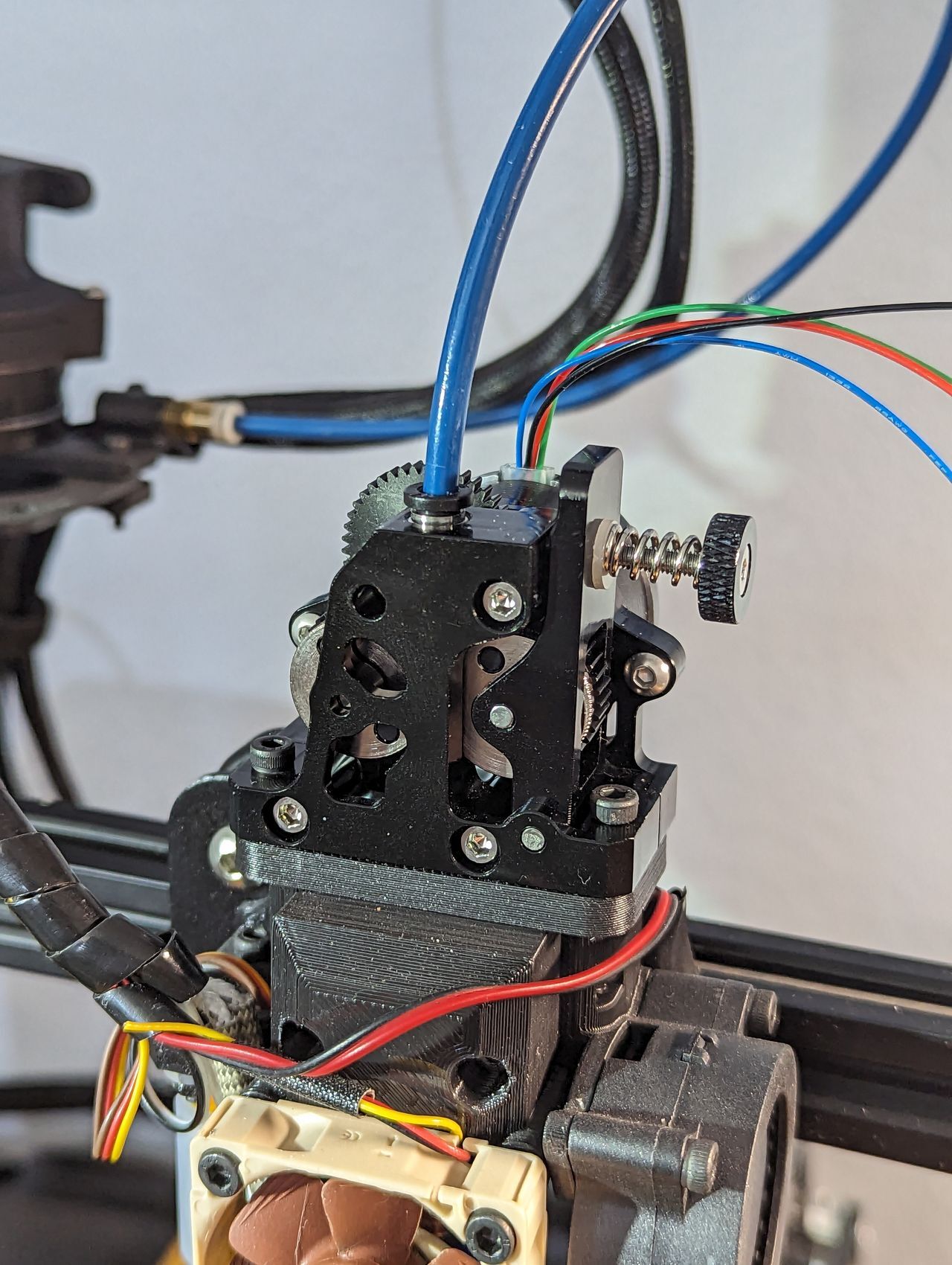

Recently I haven’t been overly happy with the extrusion consistency of my Orbiter v1. After watching a particularly enlightening video by MirageC I decided to look into updating to an extruder using an IGDA (Integrated Drive Gear Assembly) which potentially reduces the problem that Mirage noticed of non-concentricity caused by gears attached to shafts using set screws. This led me to randomly browsing ali express for ideas and I came across a semi clone of the Bondtech LGX lite called the HGX-Lite. It’s not an exact copy and uses a thumb screw to tension the gears instead of Bondtech’s lever system. This seems like a more robust design in my opinion, although I haven’t used the LGX. It seems to go by various brands. I bought a “Haldis”.

I printed Mihai’s extrusion test, and it shows an enormous improvement in consistency over the Orbiter. I’ve taken a photo with glancing lighting to exaggerate the problem - the orbiter is on the right and HGX on the left. Very happy with the result so far.

Only problem I currently see is the backlash might be worse. I’m not sure how to test this or what effect it might have on print quality - advice welcome.

Disclaimer: Not saying the orbiter is bad, I loved it and it’s quite possible the V2 is better re: consistency than my original version, although it still does use a set screw in the design.

Here’s a picture of the extruder (ignore the mess of wires - testing before committing to a rewire)