It may be worth going a little hotter. I do 245° (250° if a steel nozzle) and 5° hotter for the first layer. Part cooling no more than 20% except for bridging. I dry it it 60° with plenty of hot air flow.

- 0 Posts

- 3 Comments

Joined 19 days ago

Cake day: November 5th, 2024

You are not logged in. If you use a Fediverse account that is able to follow users, you can follow this user.

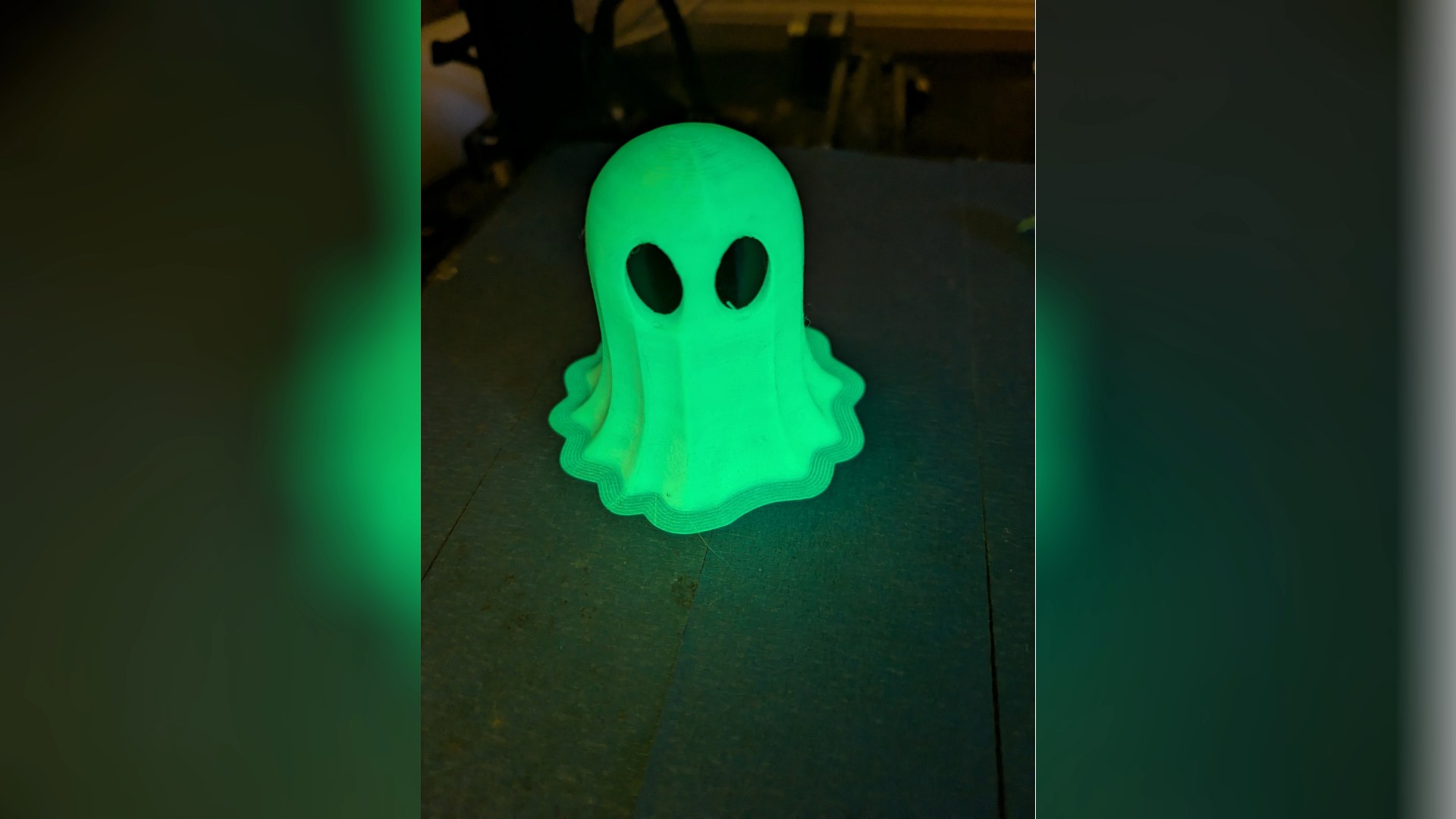

I’ve been experimenting with that sort of thing. I’ve been experimenting with a slicer and g-code hacks to do inlays and other simple multi-color prints with just one swap per color. It looks like at least some printers could manage OP’s print OK. One of my tests was a jack-o-lantern.

I got really good results with CC3D GID PETG and a steel nozzle.