I suppose you could take it off the bed, measure very precisely the height, print just the remainder (by altering the model and re-slicing) on the bed, and glue it to what’s already printed. It would almost definitely still have a visible seam and aside from that, I can’t think of a way to save it.

- 0 Posts

- 41 Comments

0·4 months ago

0·4 months agoGenerative AI is cringe now. You must not have gotten the memo.

16·5 months ago

16·5 months agoWell, yeah. It’s OpenSea. That’s like saying “76% of videos on Pornhub are porn.”

Someone needs to teach me this trick of buying pizza with the pizza’s own money.

“Dominoes hates this one weird trick.”

Never have I acquired a bit of head canon so quickly and permanently.

5·5 months ago

5·5 months agoHonestly it doesn’t seem like there’s a lot of risk with giving it a try. If it doesn’t work out, you can always buy regular commercially-available keycaps later.

You mentioned the potential of stems breaking off in the switch. I kinda doubt that’s terribly likely. (If they break off, I’d think the chunks that broke off would be big enough that they wouldn’t end up in the mechanism of the switch and could just be shaken out or retrieved with needle-nose tweezers.) That’s just speculation on my part, but I have plans to print myself some self-designed keycaps (and a self-designed keyboard base, in fact) at some point out of PLA and I’m not terribly concerned about that potential issue. I also don’t really mind buying more keycaps later if I need to, though.

3D-printed keycaps can also be replaced easily. If you’re concerned about them breaking, you might want to print some extras up front so you don’t have to wait for a print to finish before you can use your keyboard again. (And so you don’t have to try to use it with one keycap missing. Lol.)

For a second there I was worried there was something I hadn’t heard about Robert Downey Jr.

13·5 months ago

13·5 months agoAI has already peaked. It’s all downhill from here.

What I’ve used for this purpose is one of these. And I can attest that 60C° is nowhere near high enough to set that kind of thing for purposes of getting a Google Pixel 3a off safely.

But I bet ThetaDev is right that a flat plate heater can work just as well when set to lower temperatures because they heat the whole screen at one time.

Doesn’t that require a much higher temperature than most beds would be able to safely achieve.

I had to take the screen off of a Pixel not terribly long ago to replace the battery. I used a heat gun and I remember it requiring a temperature of like… 240C° or some such? And when I’m printing PLA, my printer bed only gets to 60C°. (Not saying it couldn’t go higher, but 240C° seems way higher than 60C°.)

A small triangle of tape, or just tape adhesive?

I’d definitely be more inclined to think tape could be more of a concern than jist the adhesive. Probably if it were me, I’d just try to be more thorough about removing all the tape from the spool (and not worry about small amounts of residual adhesive.)

Also, a description and/or picture of the filament and tape you’re talking about could help.

Would it really cause problems if it did? I’m thinking if it got into the hotend (especially at the small amounts we’re talking about), it would probably just melt into the molten filament and not really cause any issues.

There are “filament filters” that are for keeping foreign materials from getting into the hotend, but they’re more for particulate things that won’t melt and might clog the nozzle. Tape residue (again, at such small quanties) surely would just flow through with the molten filament and be unnoticeable in the final prints.

765·6 months ago

765·6 months agoObligatory “install Linux” post.

I model exclusively with OpenSCAD and a shit ton of math. (Full disclosure, for some of the most absolutely complex things I’ve done, I’ve written Go code to generate OpenSCAD code. But it’s not often that I need that.) And I make some pretty complex things. I’m currently working off-and-on on a 3d-printable mechanical keyboard, for instance.

OpenSCAD, in case you don’t know, is a straight up programming language for doing CAD. It doesn’t even provide you the option to adjust anything with the mouse.

It’s hardcore, but it does the job.

They’re dying him blue to make him into a jaby.

24·10 months ago

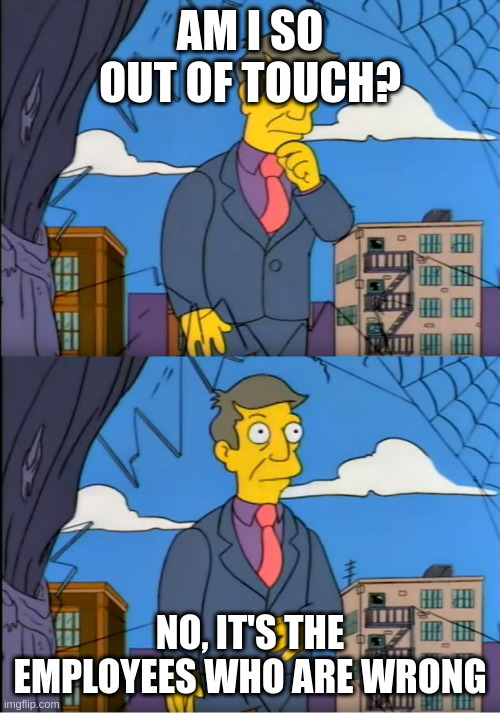

24·10 months agoThere’s going to be an article one of these days in Business Insider or something saying “employees increasingly establishing secret outside-of-the-company communication channels and sharing trade secrets over them.” And then the companies are going to get all pissy about “muh trade secritssssss” and issue nagging emails to the whole company not to set up Discords to evade their employee monitoring solution that they pay a gorillion dollars a year for. And because it was the CEO’s idea, he can’t just back down and admit it was wrong. He has to keep doubling down.

So, in other words, it does require that much computing power.

Oh sweet. Let’s just set the difficulty lower, then.

Far be it from me to dissuade anyone from applying the solution of 3D printing to any problem, but why not just buy one of those universal suction-cup-type flag car flag pole mounts and sticking it to the hatch itself?

Or maybe get a trailer hitch installed and use one of those flag poles that connect to a trailer hitch.

Mind you, those things I’m talking about tend to be made of steel. Definitely wouldn’t want your flagpole coming off on the highway or atop a bridge and impaling someone in another vehicle.

And, I’m not sure what legal considerations there might be for this venture, so it might be best to do your research. I know in my area, if anything sticks out too far out the back of your vehicle, you’re legally required to add a red piece of cloth or something. There are probably maximum lengths you may be allowed for a flag on your car.

If you insist on a 3D printed solution:

You know. Just… be careful about the whole endeavor.