Oh, I didn’t mean to come off as dissing Prusa in general. I ponied up for an XL and it’s night-and-day better than any previous printer I’ve owned.

Oh, I didn’t mean to come off as dissing Prusa in general. I ponied up for an XL and it’s night-and-day better than any previous printer I’ve owned.

If this was during an auto level, it’s my humble opinion that this is a manufacturer’s defect in the machine that caused the damage. There should be proper coding to ensure that any increase in sensor pressure by (delta p) halt that machine and that there should be a pressure offset in the sensor such that a loss of signal or anomalous zero reading or lack of reading is done prior to levelling to ensure that a sensor failure has not occurred. My XL freaks out if a fan isn’t spinning at the right speed, so they clearly know that a nominal operational check before the print starts is proper engineering design.

Of course you won’t get anywhere. Unfortunately, a lot of 3D print failures really are user error so I suspect that’s their default response and it takes them a good deal of proof to push them of that mark.

Not to defend them or minimize the corporate stupidity, but it sounded like there were less than 100k people affected out of tens of millions (100m?) accounts. I get that it was a big deal for those affected, but a 0.1% outage doesn’t seem “major”.

The description of an unexpected/(impossible) orientation for an on road obstacle works as an excuse, right up to the point where you realize that the software should, explicitly, not run into anything at all. That’s got to be, like, the first law of (robotic) vehicle piloting.

It was just lucky that it happened twice as, otherwise, Alphabet likely would have shrugged it off as some unimportant, random event.

I would prefer they brought back the actual shipping part. Not this $169/yr for “best effort 3-10 days depending on our mood” they want me to pay for.

[Raises hand]

I don’t have time to fuck with managing a seedbox to make ratios and community participation bullshit (looking at you, abt). I don’t even have time to fight incompletes on a usenet block. Let me drop a Benjamin in your “donation” box every couple of years and I’ll cover part of the server as long as I can find what I need, when I want it, in the quality I’m looking for.

I have subscriptions to a few of the big boys through legal cross-marketing deals; it’s still better to know that my shows will be waiting for me on my server if and when I ever get around to watching them.

Which is great if I were storing it and only opening the box for a new roll. I expect to open the enclosure multiple times a day when I’m working with it and the moisture would quickly require recharging. Also, since the box will be accessible for two printers sharing the volume (I might be able to isolate them, but it makes the working space more difficult) and there will be two doors it will be impossible to create it at the budget level I’m considering. Management of moisture, in this case, is a more achievable engineering solution than perfect moisture isolation.

deleted by creator

No, no - they’re not raising the price; they’re rebalancing it to reflect the value it delivers!!1!

And since they’ve reduced the free version functionality significantly, I believe I’m due a substantial rebate.

Steel ( including stainless) is up to twice as stiff as titanium - meaning it flexes half as much under load for the same thickness/shape. It’s also almost twice as heavy. To get a rigid material that is also lightweight, you need to look at exotic alloys like beryllium-aluminum, but the trade off I’d often poor toughness (fracture resistance) and difficult manufacture.

Emergency? You mean kind of emergency where I have to call my naval architect to lengthen my new summer yacht by another half a football field because I need to spend this profit windfall. -Power Co execs in TX

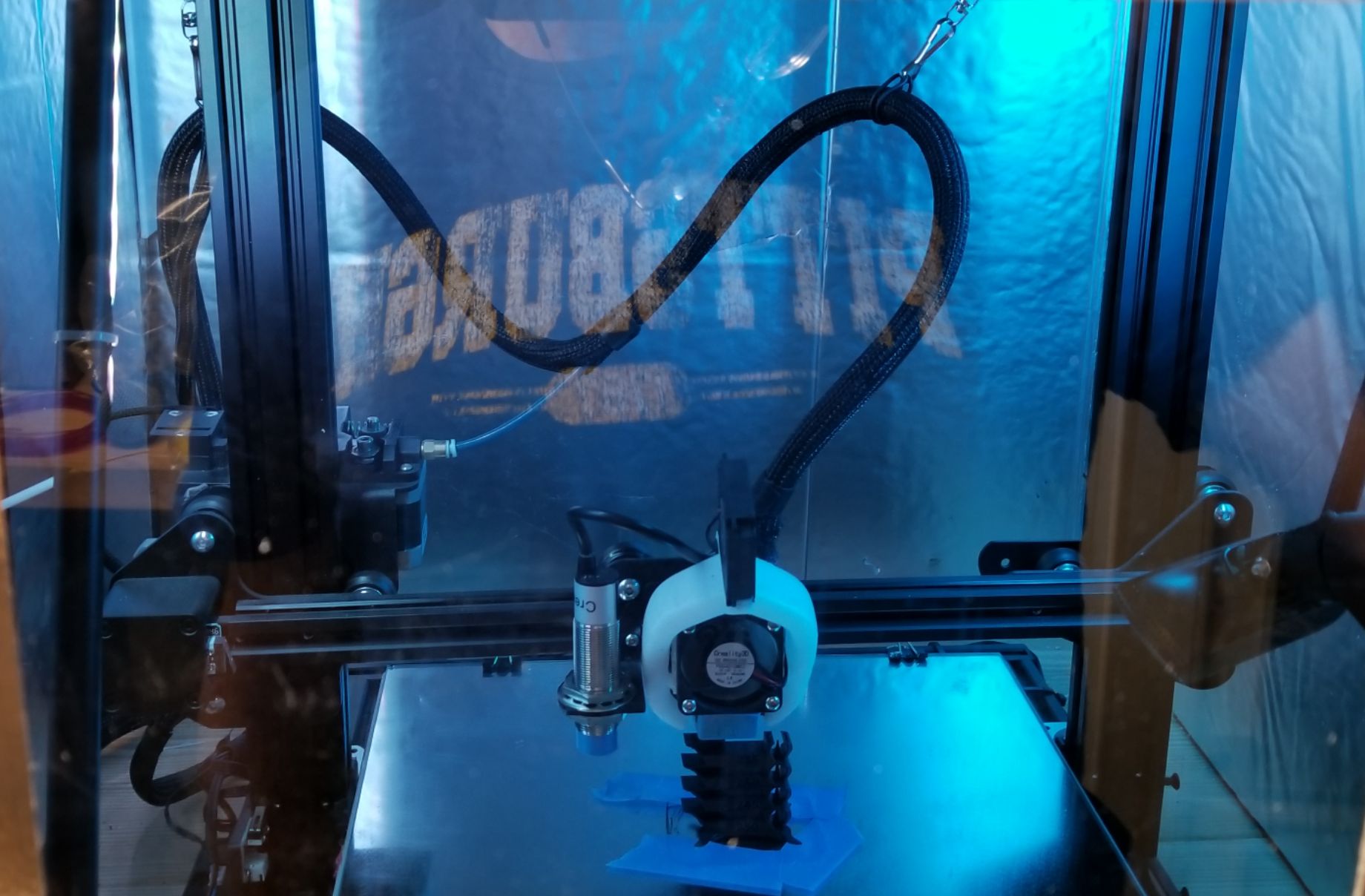

This is exactly what I do. I had a couple retractable cables let over from my wired-VR days and rigged it up on my CR10s. Works great. Here’s a pic - they tops are just connected to the top rail with a rubber band for easy removal. (this was take through the “window” in my enclosure, so you can’t see the top)

I live in a small town with a large college. The students just came back for fall semester. I believe we have quite a few candidates for your list.

Did he roll over and let them rub his belly afterwards?

I’ve owned 3 printers, all cheap. For what I spent fixing it upgrading them I could have bought a Prusa. More than saying my next printer will be a Prusa, I can say that I actually have one on preorder.

Also, I will never buy a fdm without a bed leveling function. No, it’s not necessary, but if you want a low frustration printing experience, it is - in my direct experience - essential. Prior to having abl I would keep an eye on every print start. With abl I send a job to the printer and check on it when I get around to it.

Wait, so of the five apps they will “let” you uninstall now, one makes little sense to have in the consumer edition (remote desktop - which is effectively enabled in Pro only) and one is getting deprecated (Cortana - bye bye!).

Lots of them, but normal doesn’t sell advertisements or make headlines. I see by the downvotes (or whatever Lemmy calls them) that you’ve been visited by the Reddit groupthink. It feels weird when it happens. Some of us just want everyone to get along…which feels radical in its own way.

A PR stunt until they feel things have blown over and they’ll ramp right back up.

It’s less of a stunt and more of human nature. They messed up, they realize it, they put controls in place to prevent similar errors, they get into a groove, they loosen the rules to streamline the process, they mess up, they realize it, …

This is how every single entity in every single production industry works. Financial markets? Obviously. Food Safety? Of course. Buildings and bridges? Uh, yeah. Security? In the news all the time. Submersible adventures to the Titanic? LOL. It is an exceptionally rare condition where an error and a reaction leads to a permanent chance in procedure (though they do exist).

I like my vehicles like I like my software - buy once for the features that exist now; upgrade when there is a compelling reason to do so. This rent-seeking subscription bullshit is crap.

Feel the hate. Let it flow through you.